Vats & Tables

Custom Solutions

Kusel’s custom Vats & Tables are meticulously engineered to meet the diverse needs of cheese makers, from artisanal producers to large-scale operations. Our solutions are designed to enhance efficiency, ensure uniformity, and uphold the highest standards of sanitation throughout the cheese-making process.

Key Features:

- Precision Temperature Control: Our vats are equipped with advanced heating and cooling systems, allowing for precise temperature regulation essential for various cheese types.

- Robust Stainless-Steel Construction: Crafted from high-quality stainless steel, our vats and tables offer exceptional durability and corrosion resistance, ensuring longevity in demanding production environments.

- Customizable Designs: We provide tailored solutions with various sizes and configurations to meet specific production requirements, ensuring seamless integration into your existing processes.

- Enhanced Sanitation Features: Designed in accordance with 3-A sanitary standards, our equipment features smooth surfaces and minimal crevices to facilitate easy cleaning and maintain strict hygiene protocols.

- Efficient Agitation Systems: Our vats can be equipped with advanced agitators to ensure uniform curd formation and consistency, critical for producing high-quality cheese.

Vats & Tables Custom Solution Gallery

Double O Vat

Kusel’s enclosed cheese vats are available in sizes from 15,000 lbs/ 6,800 kg. to 50,000 lbs./22,700 kg. The vat is a vertical type vat consisting of two overlapping cylinders with a vertical shaft in the exact center of each cylinder. Stirring and cutting are accomplished by the unique “sweeping curve” vertical blades. Stirring is maintained in the forward direction while cutting is completed in the reverse (opposite) direction. The vat is designed with complete sanitation in mind. Sanitary bottom bearings on the vertical shafts provide perfect alignment at all speeds and under all conditions. Kusel’s heating system introduces low pressure steam to both the bottom and sides of the vat, providing for more uniform heating.

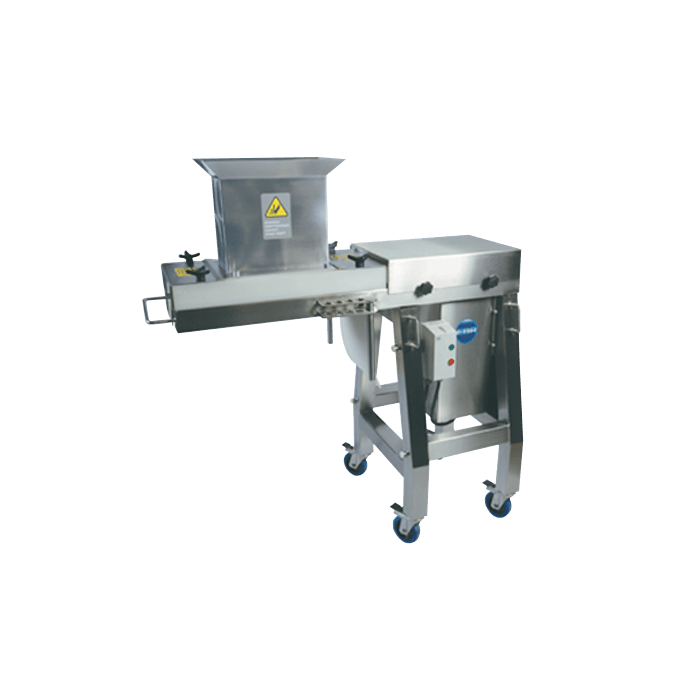

CK Open Vat

Open cheese vat with direct low pressure steam heating. Units are available with round or square ends in widths from 56” to 66” and lengths from 12’ to 30’. Depth can vary from 22” to 34”. Designed to work with The SR agitator.

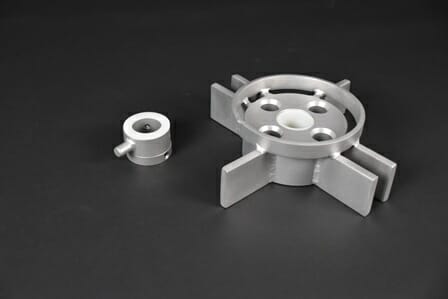

Weldment, Paddle Shaft

This paddle hub and shaft combo is utilized in vats that only require stir paddles.

Uncocking Stop Modified

The manual stops can be added anywhere in the 2M3 Finishing Table Agitator track to limit or control the agitator travel.

2M4 Agitator Curd Mover Bracket

Finishing Tables can be outfitted with curd unloading blades by being attached to the curd mover bracket.

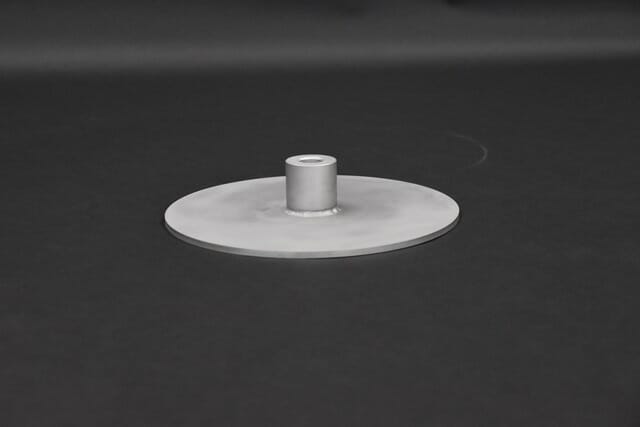

Curd Unloading Blade

Curd unloading blade is used to move the curd from the table into any type of curd handling equipment, such as curd elevators or air veyors.

Idler Sprocket Assembly

Idler sprockets allow for the traversing chain to easily glide the agitator carriage back and forth in the tracks of vats, and tables.

Guide Roller Wheel

Cheese equipment agitator carriages travel throughout the track system and rides on solid wheels with bearings for smooth ride and long life.

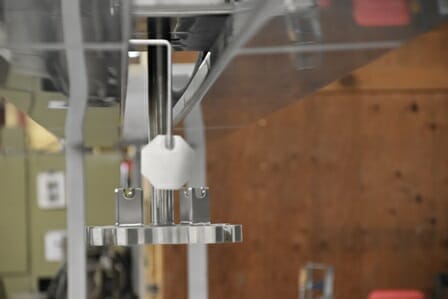

Paddle Holder Assembly

This unique paddle holder can also hold curd knives that allows the vat’s agitator to power the curd knives during the cheese cutting process.

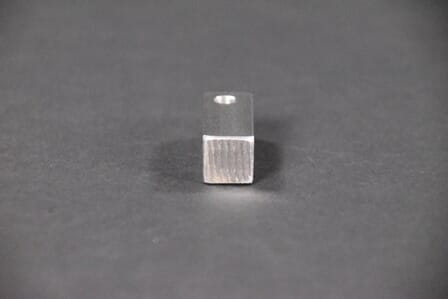

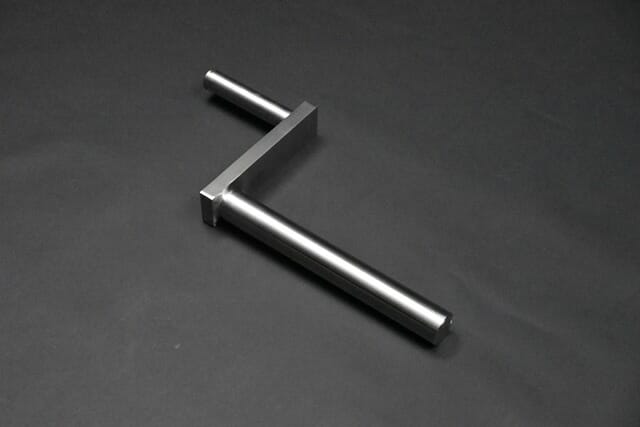

Paddle Hub Shaft

Agitators utilize strong but precision machined paddle shafts to uphold working product in vats and finishing tables.