Custom Cheese-Making Solutions

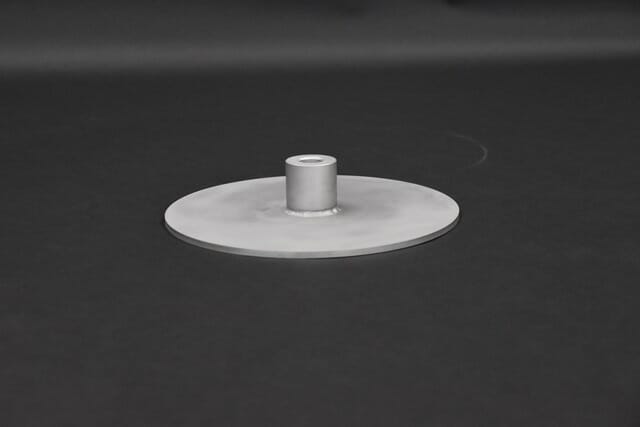

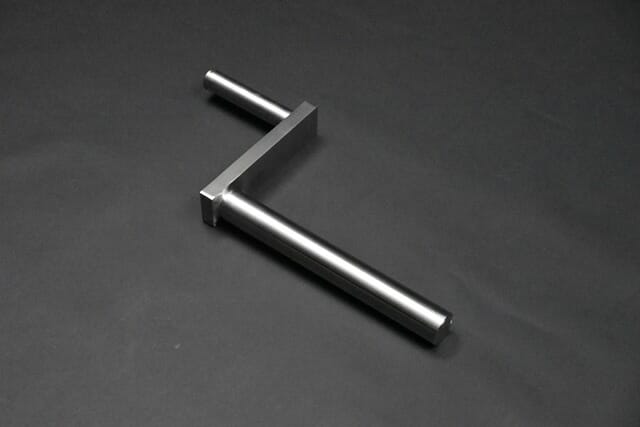

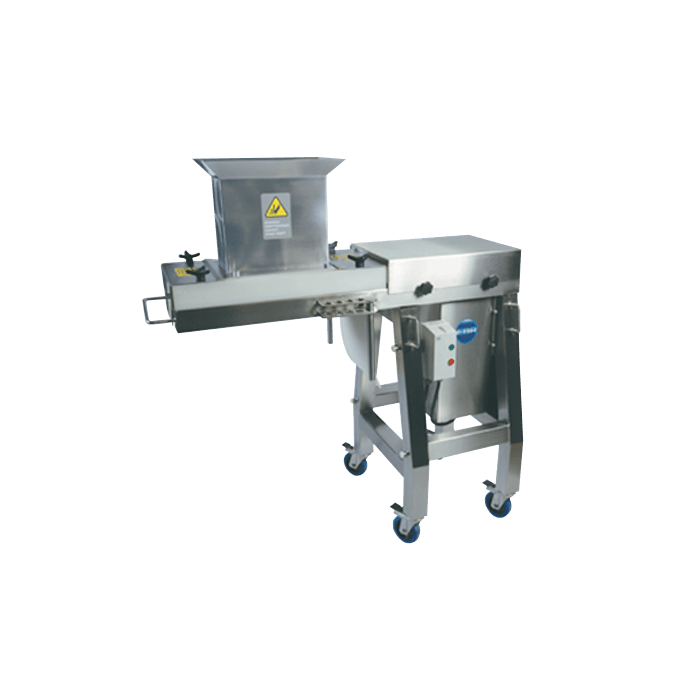

Kusel’s cheese-making equipment is designed to meet the rigorous standards of the dairy industry, combining durability, efficiency, and sanitation. Crafted from high-quality stainless steel, our solutions are tailored to enhance every step of the cheese production process. From vats & tables to curd handling equipment and pressing, or our complete cottage cheese system’s stirring paddles to pressing plates and agitators, we work closely with customers to create equipment that meets their specific needs. Explore our gallery to see how we’ve delivered custom solutions for the cheese-making industry.

Key Features:

- High-Quality Stainless Steel Construction: Built for durability, longevity, and easy cleaning.

- Customizable Designs: Tailored equipment to match unique production requirements.

- Specialized Components: Includes stirring paddles, pressing plates, agitators, and more.

- Precision Craftsmanship: Ensures optimal performance and compliance with industry standards.

- Industry Expertise: Decades of experience delivering solutions for the dairy industry.